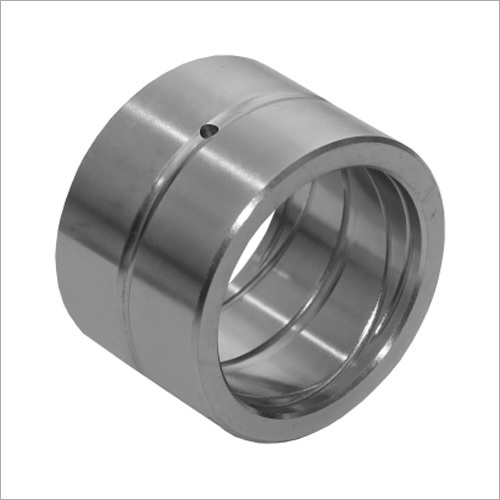

Bush Oil Grooves

Bush Oil Grooves Specification

- Lubricating System

- Integral oil grooves for self-lubrication

- Noise Level

- Low Operation

- Features

- Anti-friction, enhanced lubrication, wear-resistant

- Shape

- Cylindrical

- Size

- Custom sizes available

- Usage & Applications

- Hydraulic equipment, machinery, engines, pumps, automotive components

- Capacity

- Depends on dimension and material hardness

- Diameter

- Custom / as required

- Surface Finish

- Precision ground / smooth

- Product Type

- Bush with Oil Grooves

- Material

- Bronze / Brass (customizable on request)

- Technology

- Casting, Machining with Internal Grooves

- Power Source

- Manual

- Pressure

- Up to 8 MPa (depends on size & application)

- Surface Treatment

- Polished / as per requirement

- Dimension (L*W*H)

- Custom as per order / drawing

- Weight

- Varies by size and material

- Color

- Golden / Yellowish Brass or Bronze

- Groove Pattern

- Internal axial, circumferential, or custom grooves

- Installation Method

- Press Fit / Slide fit

- Groove Depth

- As per drawing/specification requirements

- Design Type

- Customizable with Straight, Spiral, or Chevron Oil Grooves

- Tolerance

- ±0.01 mm or as specified

- Compatibility

- Suitable for various types of shafts and housings

- Corrosion Resistance

- High (depending on base material)

- Hardness

- 60-200 HB (as per material type)

- Max Operating Temperature

- Up to 250°C

Bush Oil Grooves Trade Information

- Minimum Order Quantity

- 1000-3000 Pieces

- Supply Ability

- 300 Pieces Per Day

- Delivery Time

- 15-30 Days

About Bush Oil Grooves

Superior Performance & Applications of Bush Oil Grooves

Bush Oil Grooves champion the competition with their primary advantages: enhanced lubrication, anti-friction design, and high corrosion resistance. The application method is straightforwardchoose between press fit or slide fit for optimal installation. Their versatile usability soars across machinery, pumps, automotive components, and hydraulic systems. Customization ensures every proposal amount meets exact operational requirements, offering wear resistance and longevity for any industrial setting.

Certifications, Packaging, and Export Markets for Bush Oil Grooves

Each Bush Oil Groove is meticulously produced under stringent quality certifications, ensuring a product worthy of its list price. Secure, export-grade packaging promises intact arrival worldwide. Our main export markets include Europe, the Middle East, and Southeast Asia, where the products reliability and superior performance garner repeat proposal amounts. Certified, precision-packed, and globally acclaimed, these bushings are readily available to champion your operational needs wherever required.

FAQs of Bush Oil Grooves:

Q: How are Bush Oil Grooves installed in equipment?

A: Bush Oil Grooves can be installed using either a press fit or slide fit method, depending on the application and precise fit required in shafts and housings. Refer to technical drawings for specific installation procedures.Q: What competitive advantages do Bush Oil Grooves offer?

A: They provide enhanced self-lubrication, anti-friction surfaces, high corrosion resistance, and exceptional wear resistance. These qualities ensure reliability and longevity in demanding industrial environments.Q: Where can Bush Oil Grooves be used?

A: They are highly recommended for use in hydraulic equipment, engines, pumps, machinery, and various automotive components, making them suitable for a wide range of industrial applications.Q: What is the process of customizing Bush Oil Grooves?

A: Customers can specify groove pattern (straight, spiral, chevron), material (bronze, brass), size, groove depth, and surface treatment during procurement. Each order is manufactured to meet the exact technical drawings and requirements supplied.Q: When will my order for Bush Oil Grooves arrive?

A: Arrival times depend on the order quantity, customization specifics, and destination. After confirming the list price and proposal amount, our team will provide a precise delivery timeline upon order placement.Q: What type of lubrication do these bushings utilise?

A: Bush Oil Grooves have integral oil groove designs that utilise self-lubrication, which reduces maintenance needs and supports low-noise, smooth operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fabricated Machined Parts Category

Fabricated Machinery Parts

Minimum Order Quantity : 10003000 Pieces

Size : Custom sizes available

Product Type : Other, Fabricated Machinery Parts

Noise Level : Silent operation

Technology : Other, Fabrication

Power Source : Other, Mechanical

Counter Shaft

Minimum Order Quantity : 10003000 Pieces

Size : Custom / Standard Sizes Available

Product Type : Other, Counter Shaft

Noise Level : Low

Technology : Other, Precision Machined

Power Source : Other, Mechanical

"Manufacturing, Exporting & Supplying a wide range of Engineering Components, CNC Machined Components, Precision Auto Turned Parts, Precision Auto Turned Components, Fabricated Machined Parts, Bucket Pins Made as per customer's drawing or samples."

ALL THE PARTS ARE MANUFACTURED AS PER CUSTOMER'S DRAWINGS OR SAMPLES.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese