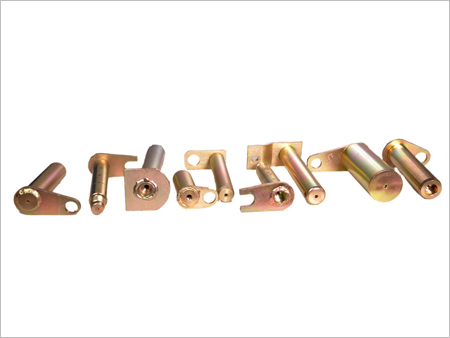

Digger Bucket Pins

Digger Bucket Pins Specification

- Corrosion Resistant

- Yes

- Standard

- IS 2062 / ISO 9001

- Thickness

- Custom as per requirement

- Tensile Strength

- up to 900 MPa

- Grade

- EN19, EN24, or as required

- Surface Treatment

- Zinc Plated / Hard Chrome Plated

- Drive Type

- Push fit / Press fit

- Capacity

- Suitable for various earthmovers & excavators

- Shape

- Cylindrical

- Load Capacity

- Up to 10 Tons

- Hardness

- 55 - 60 HRC

- Feature

- High Durability, Precision Engineered

- Diameter

- 25 mm to 80 mm

- Finish

- Polished / Blackodised

- Thread Type

- Non-threaded

- Head Type

- Round / Flat / Custom

- Fasteners Type

- Bucket Pin

- Material

- Alloy Steel / Mild Steel

- Tolerance

- 0.01 mm

- Application

- Digger buckets, Construction machinery

- Customization

- Available as per drawing/specification

- Manufacturing Process

- CNC Machined, Induction Hardened

- Packaging Type

- Wooden Box / Carton

- Usage

- Heavy Duty Applications

- Wear Resistance

- Enhanced wear life with heat treatment

- Length

- 150 mm to 600 mm

- Color

- Silver / Black

- Minimum Order Quantity

- As per buyer requirement

Digger Bucket Pins Trade Information

- Minimum Order Quantity

- 1000-3000 Pieces

- Supply Ability

- 300 Pieces Per Day

- Delivery Time

- 15-30 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Middle East, Africa, Eastern Europe, South America, Western Europe, Asia, Central America, North America, Australia

- Main Domestic Market

- All India

About Digger Bucket Pins

Being a quality centric organization, we are affianced in manufacturing, exporting and supplying a broad array of Digger Bucket Pins. The offered pins are manufactured using the best quality raw materials and modish techniques at our well equipped manufacturing unit by our diligent professionals. These pins are widely used by our clients for fastening components together. Further, our clients can get these Digger Bucket Pins at marginal prices from us.

Features:

- Rust proof

- Easy installation

- Fine threading

- Highly durable

Precision Manufacturing and Durability

Our digger bucket pins are crafted using advanced CNC machining and induction hardening techniques to achieve high durability and a precise tolerance of 0.01 mm. Material choices such as EN19 and EN24, along with heat treatment and surface finishing (zinc or hard chrome plating), ensure exceptional wear resistance and long service life on construction sites.

Versatile Applications and Customization

Suitable for a wide range of earthmovers and excavators, these pins are adaptable to various designs, with options for round, flat, or custom heads. Whether you need a standard solution or a pin made to your unique drawing and specification, our customization services, including finish and thickness adjustments, are designed to meet any heavy machinery requirement.

FAQs of Digger Bucket Pins:

Q: How are digger bucket pins manufactured for enhanced durability?

A: Digger bucket pins undergo CNC machining for precise dimensions and induction hardening for increased surface hardness, ensuring superior wear and tear resistance even under intense working conditions.Q: What materials and grades are used in these bucket pins?

A: Our pins are made from high-grade alloy steel or mild steel, such as EN19 and EN24, tailored as per application needs. These grades provide the required strength and reliability for heavy-duty use.Q: When should I consider customizing my digger bucket pins?

A: Customization is recommended when your machinery or application requires specific dimensions, head types, or finishes. We offer bespoke solutions based on your drawings or specification to ensure optimal compatibility and performance.Q: Where can these bucket pins be used effectively?

A: These pins are ideal for use in digger buckets, earthmovers, and construction machinery. They support various equipment types in demanding environments, including excavation, quarrying, and heavy lifting.Q: What is the process for ordering and packaging these pins?

A: You can place an order based on your requirements; the minimum order quantity is determined as per the buyers needs. Pins are securely packed in wooden boxes or cartons to protect them during transit.Q: How does the heat treatment enhance the wear resistance of the pins?

A: Induction hardening and heat treatment increase the surface hardness to 5560 HRC, significantly boosting the pins wear resistance and extending service life, even in harsh operational conditions.Q: What are the key benefits of using these bucket pins in heavy machinery?

A: Our bucket pins deliver high durability, precision engineering, robust load capacity (up to 10 tons), and corrosion resistance, contributing to reliable machine operation and lower maintenance downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bucket Pins Category

JCB Bucket Pins

Minimum Order Quantity : 10003000 Pieces

Material : Other, Alloy Steel, Carbon Steel

Surface Treatment : Other, ElectroGalvanized, Chrome Plated, Heat Treated

Excavator Bucket Pins

Minimum Order Quantity : 10003000 Pieces

Material : Stainless Steel

Surface Treatment : Painted

"Manufacturing, Exporting & Supplying a wide range of Engineering Components, CNC Machined Components, Precision Auto Turned Parts, Precision Auto Turned Components, Fabricated Machined Parts, Bucket Pins Made as per customer's drawing or samples."

ALL THE PARTS ARE MANUFACTURED AS PER CUSTOMER'S DRAWINGS OR SAMPLES.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese